Bronze Hot Patina sculptures can be seen everywhere in decoration

The cast copper (bronze/brass) sculpture is one of the best decorations for interior or outside space. Add they have a hot Patina color. Casting sculpture decorations is a language that is familiar to humans. And a skill that has been with us since ancient times. Hot bronze sculpture patina color can be hung in the hall to increase the beauty of the space. Can also be placed on the wall to enrich the expressive force of the wall. Be placed in the most obvious position in your garden. Put inconspicuous corner again. In short, casting copper sculptures can be placed everywhere.

Why patina surface for copper sculpture?

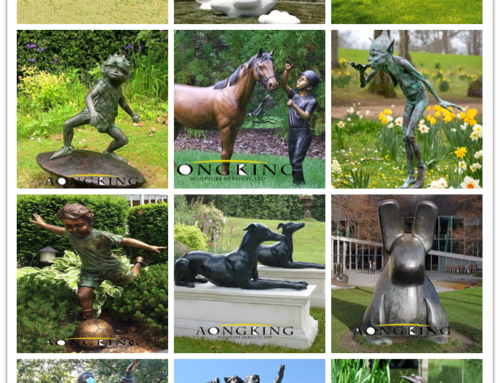

The most important and valuable technique of hot bronze sculpture patina color. The interior or outside space is to harmonize with the interior architectural space. In other words, the sculpture’s key point is to find the space that needs to be decorated most and determine its position in the interior. Outdoor put sculpture according to the space to determine the correct scale and body sense of quantity. The color of the copper sculpture is particularly important. And necessary to find the best tone in harmony with the indoors and outdoors.

The best fine bronze metalwork sculpture of art after processing molding. Usually, it is necessary to choose a fine suitable patina color for the design requirements of the artist. This way, not only improves the aesthetic effect of the sculpture artwork but also plays a role in protecting the surface of fine sculpture. For this reason, the post-processing surface technology of patina sculpture is divided into coloring technology and surface texture technology. Coloring to ensure beauty, texture processing to ensure a long and durability. In this article, we will focus on the patina surface for sculpture.

Patina surface for copper sculpture (Bronze/Brass )

The patina sculpture surface copper (Bronze/Brass ) or copper thermal coloring, also known as patina color, is modeled after an antique. That is to use chemical, electrolytic, physical, mechanical, and heat treatment methods. A film, coating, or coating that produces a variety of colors for the sculpture surface. Patina’s method is more. The appellation is also different. Often depending on the means of treatment and color source for bronze sculpture. Generally can be divided into coating (including spraying) thermal coloring, chemical coloring, electrolysis coloring, electroless plating, electroplating coloring, vacuum coloring, vacuum plating gold, and gold coloring technology. Among, the most commonly used are chemical coloring, dyeing, and heat treatment coloring for bronze sculpture. The traditional coloring methods are many. Especially in copper and copper alloy artworks are more widely used.

How Patina surface for copper sculpture (Bronze/Brass )?

1>Pre-patina treatment for copper(Bronze/Brass) and copper(Bronze/Brass) alloy castings

In order to ensure that the copper(Bronze/Brass) sculpture surface can form a uniform color, good combination, and strong corrosion-resistance coloring layer. Before that, the surface of the copper(Bronze/Brass) sculpture must be pretreated with oil removal, erosion and rust removal, polishing copper (bronze/brass), and so on. There are a variety of oil removal methods, which generally can be selected according to the appropriate conditions and the size of the copper(Bronze/Brass) sculpture.

1-1>Wipe and remove oil: use a brush or cloth dipped in detergent, washing powder, lime slurry, magnesium oxide, and other degreasing substances to wipe the oil on the copper (Bronze/Brass) surface of the copper(Bronze/Brass) sculpture. It is mainly used for the deoiling of copper(Bronze/Brass ) sculptures with large volumes, complex shapes, and difficult to be processed by other methods.

1-2>Drum oil removal: put the copper(Bronze/Brass) sculpture into the drum of the polishing machine, and add appropriate abrasive and oil removal. Suitable for large batches, and small sizes, not easy to deform art casting oil removal.

1-3>Ultrasonic oil removal: it can remove the oil in the fine hole and the hole, and the metal corrosion on the surface of the copper(Bronze/Brass ) sculpture is small. Suitable for oil removal of small art castings.

1-4>Sulfuric acid method: Sulfuric acid can remove the oxide and rust on the surface of the copper(Bronze/Brass ) sculpture.

1-5> Etching or pickling process(Chemical coloring is the most common sculpture surface decoration method for copper sculpture and copper alloy).

1-5-1> Sulfuric acid method for sculpture surface: Sulfuric acid can remove the oxide scale and rust on the surface of the copper(Bronze/Brass ) sculpture.

Firstly, pour water into a large hard glass container. Secondly, sulfuric acid is slowly into the water (equivalent to the amount of water). Dissolve the sulfuric acid solution to remove the oxide scale. It must be washed with clean water. The etching time is about 30 seconds. If the production of gold, silver, and other different sculpture copper(Bronze/Brass) sculpture, need to prepare different acids. If the same acid solution is used for a long time, the concentration of the liquid will decrease. So the solution must be remodeled frequently. Copper etching can be used to brush the copper(Bronze/Brass) sculpture with a metal brush. Wash dilute sulfuric acid with clean water and dry it.

1-5-2:Preparation of nitric acid solution: the same steps as the production of sulfuric acid solution.

Our handlers can not be rapidly poured and do not let the water directly touch the sulfuric acid. Because sulfuric acid spatters easily cause scalds or spray on the clothes will burn holes in the solution for handlers. It can burn the skin. So, handlers hand sure to use rubber gloves to protect themselves and handle with extra care and can not touch the liquid.

2> Cold or thermal colored for copper (Bronze/Brass ) sculpture and copper alloy castings

The cold coloring reaction is slow, and the film generated is stronger. Thermal coloring reaction is fast, and the film is thicker, but not strong. So Aongking is used to dilute the concentration of the coloring liquid to make the color layer strong and durable.

2-1> Cast patina sculpture (Bronze/Brass ) chemical coloring process (one of the cold coloring methods of copper sculpture):

Aongking worker first uses sandpaper to rub the surface of the patina sculpture (Bronze/Brass ). They are pickled with dilute sulfuric acid. Scrub it with a metal brush. Then wash the dilute sulfuric acid with clean water. The relief is then air-dried (scrubbed with sodium sulfide (crystals) several times. Make the copper skin black, and then naturally dry. Make the effect simple and dignified. Then use the metal cleaning ball to scrub the high point of the patina sculpture (Bronze/Brass ). So as to polish it to enhance the sense of layers of the patina sculpture (Bronze/Brass ), and then waxing anti-corrosion or spraying transparent paint and other post-processing

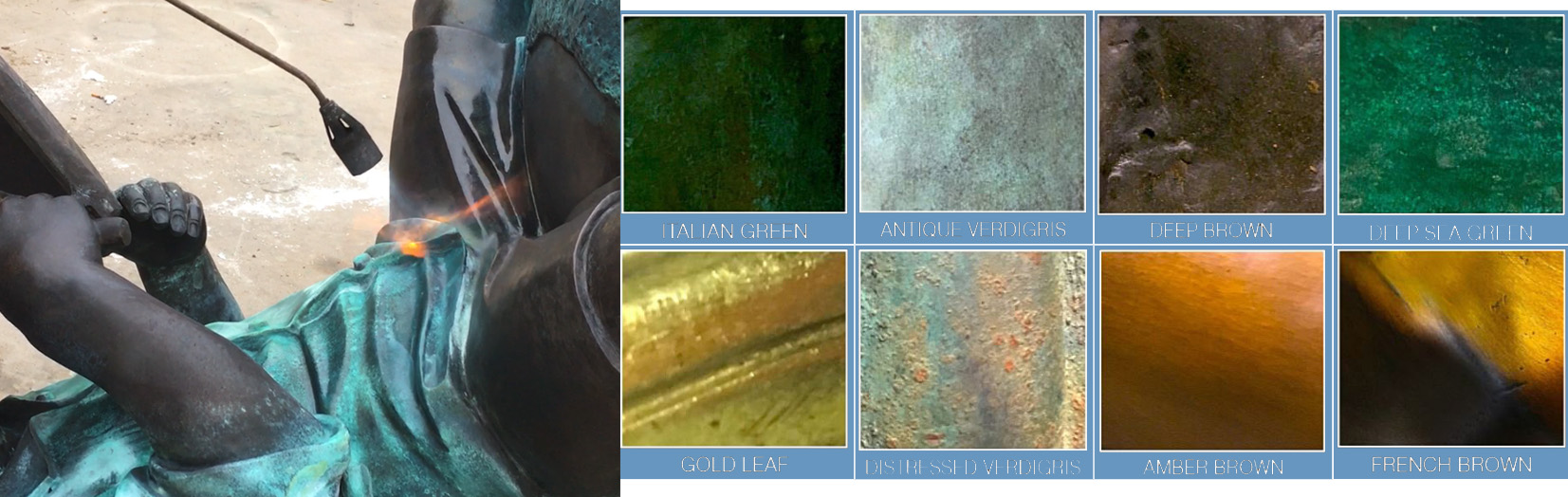

2-2> Cast patina sculpture chemical coloring process (the thermal coloring methods of copper sculpture):

2-2-1> Patina sculpture different coloring formula.

We are well known. The patina color sculpture is the color formed by the metal compound reaction itself. A fine sculpture surface has already formed as a stable metal compound. Copper sculpture thermal coloring is generally a potassium permanganate coloring formula. Potassium permanganate at high temperatures produces reddish-brown manganese dioxide. Aongking has many kinds of potassium permanganate coloring formulas. (Maple (light brown), belowChestnut (dark brown), Sandqreen (antiqued beige/green), Verdigris (natural bright greenish-blue), French Brown (two-tone light and dark brown), Anthracite (very dark almost black), Italian Green (dark green) )

Not all formulas are suitable for all situations. For example, a very nice warm red color for a sculpture. Generally potassium permanganate, and copper sulfate composition of coloring formula. This formula is only suitable for the thermal coloring of copper sculpture with more than 70 percent “CU” content. But the application of copper alloy sculpture is not ideal. We need a fine warm red color for the copper alloy sculpture. Aongking’s worker must dezincification of copper alloy sculpture and added some chlorate before it can be thermal colored. Although we can get a very beautiful fuchsia color. But, cuprous chloride is easy to oxidize and decompose and change its hue. Although the copper carving coloring liquid formula is diverse. But each color formula also has its own unique usage scenarios. The principle of coloring is basically the same. While promoting the formation of copper oxide, Aongking also to the high stability of copper oxide during the past 30 years. So the color scheme is stable.

In conclusion, a fine patina sculpture coloring formula can withstand the test of time. For example, cultural relics unearthed for thousands of years. The color is still distinct, though not so bright and colorful. But it will not fade for a long time. This should be worth learning from our ancestors. Follow nature, and don’t rush into an advantage. Is the natural law that Aongking should follow in the sculpture profession.

Beautiful & fine sculpture colors, like the eyes of the bronze bull head sculpture, flashing. Different patina sculpture color is interlaced textures, like brocade belt winding.

Full of change, natural flow, and brilliant color. There is the wall street bull for sale. Like Indomitable flames. To be meek in the hands of the Aongking artist. You can see a musket in his left hand and a watering can in his right. Fluids flow naturally, stack up, and interweave. The color is colorful and mottled. Asking Aongking…

2-2-2> Patina sculpture coloring and broil.

The copper sculpture thermal coloring process is different from physical spraying coloring, coloring after the color. Looks like the inside of the copper sculpture, is rich, natural, thick, and firm, in order to achieve the color uniform and natural, this process has very strict requirements on the temperature.

Bronze sculpture’s high-temperature coloring technology has brought a great revolution to the field of copper sculpture. The bronze thermal coloring process is different from physical spray coloring. The finished color of the sculpture looks like it’s coming through the inside of the bronze sculpture. Rich, natural, massiness, firm, can reflect multi-level brown yellow color, black. Deep and light greens permeate the inside, making it beautiful and manageable. In order to achieve the color uniform naturally. Bronze thermal coloring technology has strict requirements for the surface smoothness of copper sculpture. The second is the grasp of the heat, there is a very difficult one. Different colors have different requirements for temperature. If it is too low, it will not reach the ideal color standard. If it is too high, it will burn the surface color… The color of every second is changing at any time. Broiling depends on the aesthetic judgment of the operator worker at what second to stop to achieve the desired effect. Also to temperature control. Aongking’s workers can control broiling very well during the past 30 years.

Leave A Comment